A significant portion of competition in the manufacturing sector goes beyond developing products that create positive consumer experiences and having an operational view of processes.

Building and managing networks that enable better value delivery to the customer is also a crucial element for the success of partners in a supply chain.

Supply Chain Management is a set of strategies aimed at creating synergy between the processes of these networks and partner chains, with the goal of delivering products on time, in the right place, and in the correct quantities to the consumer.

But what makes supply chain management such an important process for the strategies and objectives of agents in a production chain?

Moreover, how can one build strategies and obtain data and information in the best possible way for the decision-making process? See below the importance of supply chain management, understand its flows, and learn about the key aspects that make it essential for industries.

What is Supply Chain?

Supply chain refers to the processes a product undergoes from the acquisition of raw materials to its delivery to the final consumer.

It encompasses the methods and operations involved in manufacturing, logistics, and distribution of the product.

For all these processes to function correctly, a complete infrastructure is required.

Today, machines, systems, and professionals make up the production chain, along with an integrated network capable of enhancing communication flow between suppliers, carriers, logistics operators, and partners.

Moreover, a complete supply chain also considers more strategic sectors such as Purchasing, Marketing, and HR. In a way, each company has a specific chain that addresses its own demands and needs in a particular manner.

The Role of Industry in the Supply Chain

Industry plays a crucial role in the effective execution of processes, as its production pace is a key factor in the availability of a product at the point of sale (POS). Therefore, the maturity of management in these cases makes a significant difference.

Another important factor is good production planning, as it is a fundamental element for the industry from the perspective of effective supply chain management.

Through appropriate production planning, an industry can avoid issues such as stockouts (product shortages at the POS), ineffective product assortment, inadequate stock visibility, and poorly managed incentive campaigns.

Given these potential problems, it is up to the industry to adopt measures and methodologies that enable proper production planning, monitor products across all fronts, and obtain performance metrics that provide visibility into these products' performance.

In this way, the industry can make its production process increasingly strategic and tailored according to information from other agents in the supply chain.

The relationship between information sharing among the industry and other supply chain agents has become a constant in recent years, as it has become increasingly evident that quality data is the foundation for more efficient management.

This makes data the basis for obtaining insights that will support both short-term and long-term planning and decision-making for the industry.

Supply Chain vs. Logistics

In many cases, some managers may end up confusing the concepts of supply chain and logistics.

Although they have similar dynamics and at times even analogous functions, supply chain and logistics are distinct concepts.

What Is Logistics?

Logistics deals with issues related to each link between agents in the production chain, i.e., the relationship between the industry and its partners in the production chain, such as suppliers, distribution channels, and wholesalers.

Another aspect that logistics encompasses is the internal logistical processes of the agents. For example, an industry needs to plan its logistical processes around a supplier but also requires efficient logistical management for the production cycle of its products.

This makes logistics more localized and focused on the links between agents in the production chain, with the goal of increasing efficiency in the stages of the product cycle until it reaches the consumer.

What Is Supply Chain?

The supply chain involves a more complex process that encompasses more than just internal processes and links between agents in the production chain. In the case of the supply chain, the focus is on managing the entire network of agents involved in the product cycle.

In other words, the supply chain aims to build a stronger network that ensures not only the timely arrival of the product at the right place and assortment for the consumer but also delivers greater value and, consequently, increased competitiveness.

The main characteristic of supply chain management is its approach to integrating processes among agents in the production chain.

The processes of production, storage, transportation, purchasing, and selling a product are highly complex. Therefore, it requires specialized planning that considers all involved agents and how to optimize their functions.

Thus, while logistics seeks efficiency in more localized processes focused on the links between agents, supply chain management focuses on the administration of the entire network surrounding the product as a whole.

This makes supply chain management an increasingly important focus for companies within the production sector, including industries and their various channels in the production chain.

What Is the Importance and Benefits of Supply Chain Management?

Without a well-structured Supply Chain Management, it would be impossible to maintain the current standard of living, let alone facilitate access to goods and services.

Efficient management of the production chain impacts the entire company. After all, it is through this management that the company controls product flows. Some of the main benefits of good supply chain management are:

- Cost reduction

There is a significant reduction in storage costs related to unnecessary occupancy of warehouse space and losses from products that, for example, have passed their expiration date or have not been sold for a long time.

- Increased Competitiveness

With Supply Chain Management, your company can handle demands in the best possible way. After all, the strategy is based on this, built upon this scenario.

As the Supply Chain becomes more effective and the end consumer perceives the impact of this change, the company stands out from the competition, and new strategies can be developed.

- Increased Revenue

The company experiences an increase in profits as a direct result of the previously listed benefits. Moreover, efficient management always seeks partnerships with suppliers and carriers that provide competitive prices and product quality.

Consequently, better products arriving at the company quickly lead to more sales and more satisfactory results. Your cash flow becomes healthier. And without the need for fixed assets such as inventory or maintenance, you reduce costs.

How Does the Supply Chain Work Within a Company?

Your customer may not know this, but the merchandise they buy goes through a series of steps before it reaches their hands.

In most cases, the company does not simply purchase a product and pass it directly to the end consumer. To truly control the quality of its service and ensure a good return, the company needs to go beyond that.

Therefore, having comprehensive knowledge of the product lifecycle is crucial. What times of the year is a particular item in higher demand? What are the suppliers' lead times? Is it a ready-to-deliver product or made-to-order? All these factors are extremely important to ensure the availability of the merchandise.

Supply chain management within the company will handle all processes related to purchasing products, storage, customer order management, delivery of goods, returns, and exchanges (if necessary).

This management can occur in various ways, depending on the type of merchandise, the size of the company, and the business model. Generally, the process works as follows:

- Planning purchases based on supply and demand forecasts

- Approval and quotation of suppliers for products and/or raw materials

- Manufacturing of the product

- Storage of the product

- Sales and delivery

- Product returns and exchanges

- Collecting feedback through customer service channels to improve processes

Which Areas Integrate with the Supply Chain?

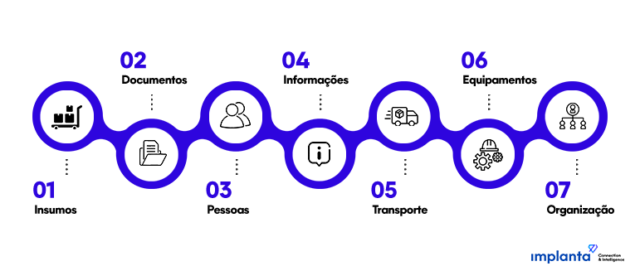

The multidisciplinary nature of the Supply Chain can be seen across various areas, elements, and specialties that constitute its stages.

1) Inputs

The inputs that serve as raw materials for production should be the foundation of the Supply Chain.

2) Documents

All steps should be documented, but not in a bureaucratic sense. The goal is to have all information at hand to enrich the analysis process.

3) People

It is the people behind each department who make the process happen.

4) Information

With the correct information, the strategic team can more easily identify where improvements can be made.

5) Transportation

Carriers must be qualified enough to meet their demands safely and efficiently.

6) Equipment

Equipment is fundamental to the production sector. It facilitates demand fulfillment and serves as tools to effectively implement the Supply Chain.

7) Organization

Although not a sector in itself, it is important that organization emerges from a collective effort in the Supply Chain. However, it should be generated by the right technology, which facilitates management and clarifies operations.

Thus, the interdependence of each of these areas is what makes the production chain a large network, requiring in-depth data analysis and high analytical capacity.

What is IBP (Integrated Business Planning)?

IBP is an extension of the principles of S&OP (Sales and Operations Planning), aiming to include the entire organization in the most effective business management. IBP is a broader concept than S&OP and operates at a higher level within the organization—not limited to sales and production.

In other words, it is the business planning process that extends S&OP principles across the entire chain, including product portfolios, customer demand, and strategic planning.

This allows for true continuous management of processes. Its goal is to align all business functions with the organization’s short, medium, and long-term goals.

Dynamically, IBP helps companies in the correct and profitable allocation of critical resources across the most crucial sectors, projects, and functions for business success and maximum customer satisfaction.

Why is Data Sharing Between Links in the Chain Important?

Companies face an increasingly competitive and complex business environment. One alternative to navigate this landscape is achieving competitive advantage through cooperation.

In this context, data sharing between links in the chain contributes to better performance among all involved agents.

Organizations can share various types of data beyond their boundaries, including both financial and non-financial information.

We know that information is essential for the decision-making process not only for the industry but also for all other links in the chain. We also know that the largest flow of data comes from consumers to distributors and producers.

Therefore, the more extensive the data sharing, the broader the strategic landscape among the links in the chain.

When done correctly and transparently, data sharing strengthens the links in the production chain and generates positive results.

What Are the Benefits of Having Visibility into Your Distribution in Indirect Channels?

In an ideal world, industries and distributors are 100% integrated in all aspects. Visibility into distribution achieves exactly this.

Distribution visibility captures data directly from the distributors' ERP systems and provides valuable information, including inventory management and sell-out metrics, which can be used by various areas of the industry, including production, trade marketing, and sales.

With this visibility, industries can reduce stockouts in their sales channels by up to 80% and monitor their products' inventory in the distributor’s or reseller’s stock on a daily basis.

Additionally, it helps decrease expired products in sales channels, thereby also reducing costs associated with losses and returns.

Thus, having distribution visibility will reduce errors in production planning and eliminate assortment shortages in sales channels.

The benefits of data sharing are numerous; your sales can increase by up to 10%, there is an average increase of 5% in profit margins, logistics improvements occur, the industry produces only what will be consumed, and data accuracy is high, optimizing decision-making.

What Can Be Learned from the Best Practices of Leading Companies?

Successful companies stand out for their extraordinary impact around the world. When we think of them, we think of Apple, Netflix, Natura, Nike. Despite being from different sectors, these leading companies share many common aspects.

Firstly, they use technology to obtain current and accurate information, which directly influences all critical decision-making. Another important factor is valuing their talent and investing in development programs.

Additionally, these companies take internal training very seriously; skilled and committed employees are crucial elements for business success.

Moreover, another fundamental point is understanding the importance of a corporate culture that does not judge mistakes.

Companies, in general, need to learn from the problems that occur, and they need to adjust if necessary. They must seize new business opportunities that arise from disruptions.

What Will the Future of the Production Chain and Industry 4.0 Look Like?

The technological resources available today are significant allies of the production chain. These tools represent a true revolution in the sector, as they are directly linked to control and planning—two crucial aspects of the field.

A clear connection can be drawn between logistics and Industry 4.0. Thanks to these advancements, it is possible to eliminate waste, identify weaknesses, and increase productivity while continually striving for improvement, another principle of industrial logistics.

To meet the growing demands of customers, companies are restructuring their production chains and moving production closer to the point of demand.

Moreover, they are changing their operational models to work in a less centralized manner than is common today. This highlights the importance of the production chain for the future success of organizations.

Organizations are increasingly adopting a multidimensional view of value creation that benefits all stakeholders, and many are developing measures to incorporate a value generation approach for everyone's benefit.

How to Apply Supply Chain Management in Your Company?

To correctly apply the concept in your company, efforts must be made to integrate the processes carried out within the organization with all others that link the participants in the production chain (trade marketing, research, finance, human resources, purchasing, sales, development, and logistics).

Companies with good logistics, performance monitoring, and technology to manage all these processes are capable of building a flexible and competitive logistics system within global economic indices.

In conclusion, data is the key for industries not only to achieve greater competitiveness but also to build strong partnerships, plan production appropriately, and make smarter business decisions.

This is the key to a more efficient Supply Chain and an increasingly strong industrial sector.

An effective production chain depends on functional solutions, and Implanta has the solution for your company. To learn more about Implanta's solutions, talk to one of our specialists now and discover the best way to manage the Supply Chain in your company!