To ensure the survival of companies in the market or to grow consistently, it is necessary to accelerate the precise discovery of errors, optimize processes, and expand communication. Only then can you achieve more efficient and competitive management.

Therefore, having comprehensive visibility throughout the production chain is vital and strategic. This applies to both the industry and distribution agents who bridge the gap between retail and industry.

But what makes visibility throughout the production chain such an important process for the strategies and goals of chain agents?

Moreover, how can strategies be built and reliable data and strategic information be obtained in the most effective and cost-effective way for decision-making processes?

See below the importance of having complete visibility throughout the supply chain and how Implanta can assist you with that.

What is a Supply Chain?

Let's start with the basics, after all, what is a supply chain?

Supply Chain is a set of operations that encompass all stages of production, storage, and transportation of products.

Current supply chains are not linear entities; therefore, they are quite complex. They involve functions such as product design, raw material and component procurement, demand forecasting, supply organization for dedicated sales channels, and support and visibility throughout the customer order process.

As a result of this complexity, there are many sources of data to track and predict supply chain activity. This includes internal data across the entire supply chain and business operations; external data from third parties such as suppliers, partners, customers, and even competitors; and economic, political, and environmental data from reliable third parties that can affect supply chain operations.

For a company to succeed in its supply chain, all departments need to be involved and must act in an integrated manner. After all, this is the only way to ensure that each stage of the chain operates correctly.

Visibility Along the Chain is Fundamental

Today, the industry lacks visibility of the complete chain, having only partial visibility up to a certain point. In other words, at a certain moment, information begins to become incomplete and data loses accuracy.

Considering that consumer purchasing behavior directly influences the entire production chain, it is essential that retail data regarding these consumption patterns be quickly shared with industries.

This way, companies can adapt their strategies to seize opportunities and mitigate potential risks.

On the other hand, it is equally crucial that information from the industry reaches the distributor without any interference and extends clearly and effectively to the retail level.

The industry develops its planning and creates strategies that primarily encompass production, logistics, sales, and marketing sectors. Therefore, there is a concerted effort to ensure that industry guidelines are transmitted through the sales force to the retailer, who needs to be in sync with the strategy to achieve the desired results.

Therefore, visibility along the chain is not just desirable; it is absolutely essential to ensure data quality and accuracy in decision-making.

Explaining Supply Chain Visibility

Supply chain visibility refers to a company's ability to obtain a detailed view of its products as they are transported from the supplier to the consumer.

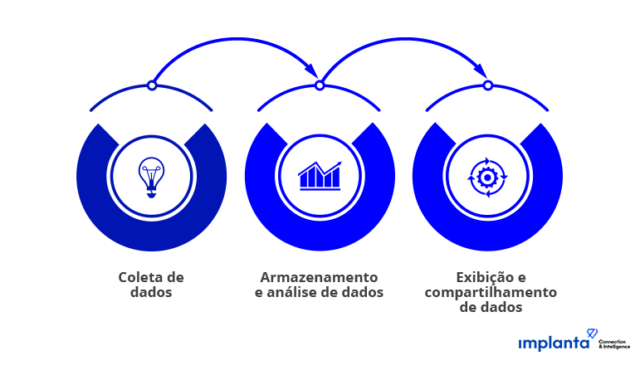

This visibility is achieved through:

Data collection: the data is collected from internal sources such as ERP, transportation management, inventory management and CRM systems; external sources including supplier data, weather patterns, customer feedback, and economic trends; and technologies.

Storage and analysis of data: all collected data is stored in a repository or management system where it can be processed and analyzed. Advanced supply chain analysis can help companies uncover profitability drivers, understand costs, evaluate order fulfillment rates and delivery performance, manage supplier risks, and assess the impact of economic, social, and environmental trends on business.

Display and sharing of data: supply chain professionals can use real-time dashboards and on-demand reports to explore business topics and specific use cases. For example, they can view expiring procurement contracts, evaluate available inventory levels, or track the percentage of product orders shipped on time.

By connecting these elements, companies can gain a comprehensive view of the efficiency of their supply chains.

Challenges of Supply Chain Visibility

Some of the biggest challenges in achieving supply chain visibility include:

Irregular data: there is no shortage of data when it comes to business operations. However, how companies utilize and disseminate this data is crucial. Disconnects between links in the chain can lead to inaccurate information and hinder the ability to obtain a comprehensive view for businesses.

Different business processes: as companies gather data from various sources throughout the supply chain and across their operations, standardization across processes and systems becomes essential. With different systems for planning, production, customer service, and other essential functions, tracking products or exchanging data efficiently between internal teams, suppliers, and other partners is challenging. As a result, companies struggle to plan with the same efficiency, adapt as easily, or meet customer expectations.

Lack of downstream visibility: the ultimate goal of any supply chain is customer satisfaction. To achieve this, companies need visibility into how their products are reaching customers. Downstream visibility includes not only end consumers but also manufacturers, distributors, and retailers acquiring the products. Manufacturers rely on retailers to inform them about demand spikes, product performance, and other factors influencing purchasing decisions and inventory. Effective supply chains implement processes and resources to receive and act on these crucial data insights.

Lack of upstream visibility: without upstream visibility—meaning insight into supplier data and challenges—organizations risk not obtaining essential parts and materials for their product manufacturing. For instance, a company needs to be aware of potential production setbacks from a raw material supplier to take necessary actions and prevent a domino effect. This requires open communication channels, collaborative tools, and a shared environment for data sharing.

Why is Data Sharing Among Supply Chain Links Important?

Companies face an increasingly competitive and complex business environment. One alternative to navigate this landscape is achieving competitive advantage through cooperation.

In this context, data sharing among different components of the supply chain contributes to optimizing the performance of all involved parties.

We understand that access to information is crucial not only for decision-making in the industry but also for all other participants in the chain.

We also recognize that the majority of data flows from consumers towards distributors and producers.

Therefore, the more extensive the data sharing, the broader the strategic landscape among the links in the chain.

When done appropriately and transparently, data sharing strengthens the links in the production chain and generates positive results.

Benefits of Having Better Visibility Along the Supply Chain

Visibility among the links of the chain brings benefits such as:

- Data standardization;

- Process automation;

- Greater operational and sales efficiency;

- Improvement in communication flow;

- Faster decision-making;

- More precise planning, with risk reduction;

- Cost reduction;

- Efficient inventory management;

- Loss reduction;

- More efficient transportation, storage, and distribution;

- Increased satisfaction of the end customer;

- Enhanced productivity;

- Greater opportunities for innovation.

More Data Intelligence, Higher Productivity

In the industry-distributor relationship, there used to be some misunderstandings due to an old and outdated culture that expected distributors to provide information without receiving proper reciprocation.

Fortunately, this mindset is changing. Day by day, more companies understand how beneficial sharing information can be.

Thus, the information requested by the industry, derived from sales data of their partners, generates important insights for all parties to benefit and achieve the best results.

We can see, therefore, how increased visibility throughout the chain benefits not only the industry but the entire production chain (industry, distributor, retail, and consumer).

Looking to improve communication among the agents in your production chain? Seek more innovative solutions that integrate these agents with a focus on sharing information across all links of the chain.

Implanta's solutions differentiate themselves with powerful data handling capabilities, providing the industry — unlike other providers — with the ability to bring value to other chain links. This ensures all necessary data for strategic decision-making through their various customized solutions.

With 99.8% accuracy, our tools collect and process data automatically and directly from distributors' and POS systems' ERPs. This data is processed using artificial intelligence on our platform and made available through customized dashboards and APIs.

To ensure your industry stays connected with technological advancements, contact us right away. We're eager to help your business evolve consistently and noticeably!