For planning to be integrated, organized, and productive, it’s necessary to follow methods that aid in this activity, with the main one being S&OP, also known as Sales and Operations Planning. S&OP, mais conhecido como Planejamento de Vendas e Operações.

But, after all, do you know what S&OP is? Why is it so important for your business's logistics? Continue reading to learn more about its benefits and advantages for the industry.

S&OP: What Is It?

S&OP, or Sales and Operations Planning, is an integrated process for managing the different areas of a business.

The evolution of this approach occurred when industries decided to integrate administrative areas with production.

In large industries, it is necessary to plan the volume of products as effectively as possible. This is because the total volume is shared across distinct areas (such as Sales, Research & Development, Manufacturing, and Marketing), and not all systems are integrated with each other.

The correct definition of resources and processes, including capacity, is related to the company's strategic decisions.

In summary, S&OP is a tool for implementing and unfolding strategic planning, adding value to the business by anticipating the company’s needs and constraints, and creating synchronized solutions with market demand and the company’s supply.

What Are the Benefits of S&OP for Your Company?

S&OP brings several benefits to a company because it allows for advance planning and anticipation of issues that may arise in the flow between sales, production, and finance.

This controlled management of actions prevents reactive measures, providing greater visibility into product supply and demand.

Similarly, the process also produces positive changes and helps departments address unforeseen issues more swiftly, while promoting teamwork through consensus-based decisions grounded in facts and data.

Additionally, a crucial point is that S&OP can significantly enhance customer service levels and inventory turnover, reducing unnecessary purchases and preventing losses due to poor product expiration management.

The improvement of the process, along with all the aforementioned benefits, also leads to better relationships between departments, which begin to work in a more integrated and collaborative manner.

6 Reasons to Adopt S&OP in Your Business

The adoption of a sales and operations planning process in the supply chain has been the best response for companies to achieve a balance between supply and demand, with an increase in the level of service offered to customers.

Among the practical examples of the benefits that adopting S&OP brings to a company, both tangible and intangible, are:

1. Accuracy in Demand Forecasting

2. Maximized Profitability, Without Excesses or Stockouts

3. Increased Storage Capacity

4. Increased Turnover of Finished Goods Inventory

5. Reduced Loss Due to Expiration for Perishable Products

6. Increased Percentage of Orders Delivered in the Quantity and on the Date Requested by the Customer

4 Tips for Successful Implementation

For the S&OP committee to be more than just an operational meeting and truly serve as strategic planning, integration between the various key areas of the company, such as Production, Sales, Marketing, Finance, Supply Chain, etc., is necessary.

Companies with mature S&OP processes achieve remarkable results, particularly in terms of reduced idle and non-productive inventory, lower freight costs, and improved productivity of both machinery and personnel.

However, despite its apparent simplicity, S&OP is complex to implement due to the various obstacles encountered before reaching the desired maturity.

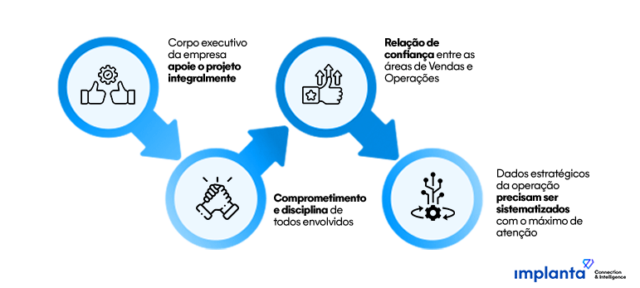

With this in mind, we would like to share 4 valuable tips for ensuring the successful implementation of sales and operations planning:

1. It is necessary for the company's executive team to fully support the project.

2. The process requires commitment and strict discipline from everyone involved, from data collection to participation in monthly meetings.

3. It is important to establish a trust-based relationship between Sales and Operations.

4. Some strategic operational data need to be systematically managed with the utmost attention, such as lead time, minimum lot sizes, and permitted inventory levels.

Companies that wish to remain competitive and financially healthy will find in S&OP an opportunity to improve their processes and manage the constraints they face day-to-day effectively.

S&OP and Technology

Finally, now that we understand what Sales and Operations Planning (S&OP) is, how it is implemented, and how it can benefit the industry, we need to explore how to make this process feasible.

Implanta has the right solution for this! The Distribution Visibility tool addresses the first part of the S&OP process: collecting data from the entire production chain.

The Distribution Visibility tool captures data directly from the ERP of indirect sales channels, providing visibility into your products by tracking inventory and sell-out data. All this with up to 99.8% accuracy in user-friendly dashboards.

With access to this data, it is possible to have a clear view of sales volume, customer engagement, purchase profiles, pricing policies, product lot traceability, market potential, shelf breaks, and product sales volume.

This allows the industry to perform operational demand planning, hold strategic meetings, and define an operational plan to implement what has been outlined in the process. This moment is crucial for shaping strategies, costs, and other determining factors.

With demand planned, a strategy set, and operations running with sales underway, the company needs to periodically monitor results to ensure the execution of the strategic plan.

In this way, adjustments will be made to correct issues and improve strategies. It is unlikely that the company will avoid mistakes in this process, but the important thing is to end up with as many successes as possible.

Want to know how Implanta can help you achieve the maximum number of successes in the process? Talk to us and discover why Distribution Visibility is the perfect S&OP solution for your company.