We know that industries need to stay vigilant during periods of significant market fluctuations, as instability in supply and demand significantly increases the risk of stockouts for distributors.

Undoubtedly, this is one of the issues that these organizations must avoid as much as possible.

One reason is that stockouts can lead to losses in credibility and finances, depending on the severity of the situation.

Therefore, careful management of the items available for manufacturing or marketing these products is crucial.

In this article, we will highlight initiatives that enable strategic inventory management, which is essential for maintaining high competitiveness. Check it out!

How Stockouts Affect Customer Relationships

It is undeniable that a lack of products leaves consumers quite dissatisfied. For example, a customer may prefer to shop at a particular supermarket because it offers a wider variety of products than its competitors.

However, when there are stockouts, it starts affecting the availability of products at the store.

This situation leads a loyal customer to seek new options to be fully served.

Whether by looking for similar products from other brands or by finding another store that has the desired product.

Another negative consequence of missing items is negative publicity.

With social media, this phenomenon has become even more pronounced. After all, a post on Facebook, Instagram, or YouTube can quickly gain significant traction, which can be detrimental to a brand’s image.

Not providing products according to the target audience's needs also harms credibility.

This effect is even more devastating when a company fails to meet its restocking deadlines as promised to consumers.

These situations highlight how seriously stockout problems should be taken by entrepreneurs.

A good manager should do everything possible to prevent product shortages from becoming routine, as neglecting customer needs results in decreased sales and profits.

Stockouts: Why Does It Occur?

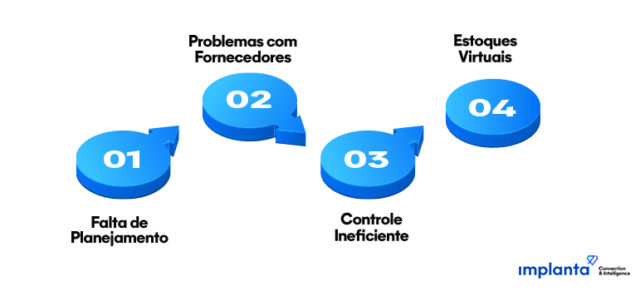

There are a range of factors that cause this problem. To help you better understand the causes behind stockouts, we will present them in a clear and educational manner. Stay tuned!

Lack of Planning

It is normal for demand to fluctuate throughout the year due to various factors, such as economic dynamics and consumer desire for certain products at specific times of the year.

If a company does not account for these scenarios, it faces a serious risk of product shortages, even during peak demand periods.

This undoubtedly underscores the importance of having a data-driven plan based on market trends and consumer behavior.

Problems with Suppliers

Choosing the right partners is increasingly crucial for achieving success in the business world. Opting for a poor supplier is a significant mistake that can be detrimental to any industry.

After all, delays in delivery are one of the most common factors associated with stockouts.

Even if your business strives to respect customer needs, a supplier's inability to meet deadlines can result in losing the trust and preference of your target audience.

Inefficient Control

Even with technological advancements, some industries still struggle to perfectly track the inflow and outflow of goods in their distribution networks.

One consequence of this failure is the absence of certain products.

If inventory monitoring does not adhere to good management practices, a company may appear unprofessional and fail to remain competitive.

Today, proper inventory control is the bare minimum expected of an organization that aims to be recognized for the quality of its services.

Virtual Inventories

Due to operational issues, many clients maintain inventory records in their ERP systems that do not reflect reality. Errors occur when orders are placed for products that no longer exist because they were stolen, lost, or not recorded in the system.

With the sell-in and sell-out controls from Implanta, the industry will have a more accurate view than the distributor or retailer itself.

How to Avoid Stockouts

It is well known that the absence of goods is detrimental both financially and in terms of reputation. Fortunately, it is possible to prevent this issue as long as the correct measures are taken. With that in mind, we will outline what can be done for your business to manage inventory without stockouts. Check it out!

Integration Between Departments

Collaboratively and intelligently sharing part of the distributor's or reseller's operational information is an excellent way to ensure that inventory always matches demand..

This integration will be achieved through Implanta IT, which will use its data extraction tool to access inventory and sell-out data directly from the distributor's infrastructure, providing valuable insights into sell-out, stock levels, and sales to the marketing, trade marketing, and commercial departments.

Mapping Goods

A company must identify high-turnover products, that is, those with higher demand.

By intelligently mapping the most in-demand items, it becomes much easier to combat stockouts.

Demand volatility for products is significant and can be influenced by factors such as price (both internal and competitive), weather, economic stability, seasonality, promotions, etc. Therefore, this mapping of goods needs digital tools to be more effective.

One reason is that the organization will have more consolidated data on how a product is capturing the target audience's interest.

This information is crucial for planning replenishment and ensuring the availability of sold items.

Attention to Seasonal Dates

Periods when commerce is busiest (such as Black Friday, Christmas, and other holidays) require more than just extra vigilance to prevent stockouts.

If consumers cannot find the desired product in a store due to management errors, they are more likely to turn to a different store or a similar product from another brand.

Good planning and a deep understanding of market trends are crucial to avoid issues with high turnover of goods during peak shopping seasons.

How Can Implanta IT Help Reduce Stockouts?

If you are genuinely interested in better managing your business's demand, a good alternative is to partner with a company that allows you to use Information Technology (IT) resources strategically.

With Implanta IT's support, you can obtain accurate and processed data regarding distribution visibility.

Undoubtedly, this is where Implanta excels, as many of its clients struggle with data handling, often referred to as the famous "De/Para."

Effectively leveraging digital transformation significantly contributes to preventing stockouts. This is a factor that corporations cannot afford to ignore under any circumstances.

As we have seen, having the right information and technology support is essential to avoid stockouts.

So, if you are looking for best practices to manage your inventory, contact us now! We want to help you achieve increasingly outstanding performance!