In logistics management, for a long time, S&OP (Sales and Operations Planning) was an indispensable tool for operational success.

However, IBP (Integrated Business Planning) has emerged to take that prominent position—establishing itself as the ideal tool for successful logistics management.

The truth is, the efficiency of S&OP has been more than proven. It is no wonder that it is so widely adopted around the world. According to the Hackett Group, about 70% of supply chain managers report adopting good S&OP practices in their companies.

And it really does make sense.

You likely encounter a routine of processes related to Sales and Operations Planning in your company on a daily basis. However, what many managers and companies have realized is that more is needed.

As an operational tool, it is argued that S&OP does not provide much support for financial and strategic business issues. In today's reality, it is necessary to rely on a robust solution that leverages semantics and data intelligence to provide truly valuable insights.

This is something a tool like IBP (Integrated Business Planning) offers. And that is why it is considered the evolution of S&OP.

In this article, we will delve a bit deeper into the topic, reviewing the concepts and parallels between the two tools, and exploring a perfect solution for the industry to anticipate market needs. Stay tuned!

Recap: What is S&OP?

S&OP (Sales and Operations Planning) is not a single tool. On the contrary, there are various interpretations of its definition.

It is a set of processes aimed at aligning sales and production departments to create an effective demand plan.

As the term suggests, it involves operational and sales planning.

S&OP exists out of a simple necessity: a successful production plan must consider demand, production capacity, and supply. This process is guided by a meeting with those involved in the company's supply chain.

Together, they review the results from the previous month (or chosen period) and integrate this information with the demand forecasts from the sales department.

Thus, methodically, S&OP is a method with the primary purpose of aligning production levels with the expected sales volume.

What is IBP – Integrated Business Planning?

And how does IBP – or Integrated Business Planning – fit as the “next step” from S&OP? Just like with S&OP, there are many definitions of IBP.

Perhaps the best way to describe it is as an extension of S&OP principles, aimed at including the entire organization in the most effective business management.

IBP is a broader concept than S&OP and operates at a higher level within the organization—not limited to sales and production.

In other words, it is a business planning process that extends S&OP principles across the entire supply chain, product portfolio, customer demand, and strategic planning.

This allows for true continuous management of processes. Its goal is to align all business functions with the organization’s short, medium, and long-term goals.

This is where one of the major differentiators of the solution comes in. The objectives and goals of IBP are measured in financial terms and naturally align with the organization’s budgets and long-term targets.

In a dynamic way, IBP helps companies allocate critical and profitable resources to the most crucial sectors, projects, and functions for business success and maximum customer satisfaction.

The Importance of IBP

IBP is a process focused on aligning the company’s actions.

The implementation processes of this strategy follow a standardized approach but should be adapted to the individual characteristics of each business.

Throughout the process, and if necessary, the involved teams must assess the results and ensure continuous analysis and adjustment of strategies.

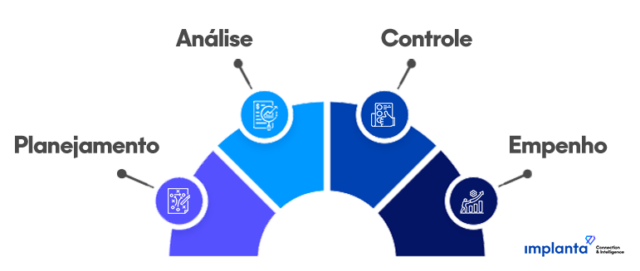

This allows for the development of a cohesive plan that aids in forecasting results and enables better management control. Properly executed work includes:

- Planning

- Analysis

- Control

- Commitment

Why the Use of IBP Replaces and Evolves S&OP Processes

While S&OP focuses more on the operational aspect of the supply chain, IBP aims to encompass all variables that could affect both deliveries and the company’s finances.

IBP can be used as a tool to provide data and structure processes that strategically and effectively guide the organization.

Its starting point is not the sales forecast in units but the organization’s financial forecasts.

Although they may represent two different measures of the same concept, where sales drive organizational success, the unit of measure and execution methods differ.

IBP naturally aligns with the organization’s financial numbers and forecasts, something that is not possible with S&OP.

What Are the Main Barriers and Why Do Companies Struggle to Adopt IBP?

The process of adopting IBP doesn’t need to be standardized, but it must address the specific problems of the company. It needs to effectively add value and enhance the organization’s processes.

Different companies will have different formats for IBP, and they will have different horizons within the IBP process.

Some companies with simpler supply chains and short-term needs will have different requirements compared to companies with more complex and longer supply chains, which need a broader visibility horizon for the process.

The first major step in adopting IBP is understanding what is truly important for your business.

Another relevant aspect is the lack of involvement from some areas. The IBP process is not solely the responsibility of the supply chain. Although the supply chain typically drives this topic within companies due to its awareness of the need for medium to long-term planning, the leadership role belongs to the entire organization.

It needs to be shared with finance, marketing, sales, and all other departments of the company.

The biggest failures in adopting IBP occur when the company treats it merely as a supply chain process, rather than as a tactical approach relevant to the entire organization for determining decision-making dynamics, alignment, and communication.

This process is necessary for the company to connect its strategy with execution.

Anticipate Market Needs with Demand Forecasting

And in practice? How can you replace your S&OP processes with a well-structured IBP that provides information to support your business?

You can rely on a dedicated platform that integrates with all business sectors to centralize data and assist with intelligent processing.

One such option is Demand Forecasting, a solution developed by Implanta.

The best approach is to leverage scientific data and artificial intelligence to plan the next steps for your business. With Demand Forecasting, this is achievable.

The tool helps the industry gather external data from various sources and acts as a comprehensive information processor.

Using AI capabilities, it assists the industry in gathering insights and developing actions to enhance the supply chain with over 90% accuracy.

This means the industry reduces logistical errors and eliminates production waste. With precise control and full demand predictability, you can improve your pricing processes.

Therefore, Demand Forecasting fits into the industry’s logistics area, as well as in sales, production, and marketing.

Would you like to see how Demand Forecasting can serve as an IBP solution for your company? Talk to us!