When it comes to the supply chain, maintaining balance and alignment between retail product demands and the replenishment provided by the industry is still a challenge.

On one side, we have retail, which needs products to be consistently stocked on shelves to avoid stockouts or excess inventory.

On the other side, we have the industry, which needs to produce quantities aligned with demand, a process that requires data monitoring with maximum accuracy.

This is where VMI-based solutions come into play. VMI methodologies help manage replenishment at points of sale and provide reliable data to meet stocking demands.

But what exactly is VMI? How does it ensure better forecasts and data-driven decision-making? Understand below how this tool could be the solution to your inventory problems."

VMI: What Is It?

VMI stands for "Vendor Managed Inventory," which literally translates to "inventory managed by the supplier" in Portuguese.

In essence, this term refers to inventory control carried out by the supplier of a particular distribution channel. This supplier could be either the manufacturer or the retailer's distributor.

Instead of the distributor having to place an order for products with the manufacturer, the manufacturer will monitor inventory turnover data to make the necessary replenishments. This allows for the optimization of the replenishment process.

Thus, one of the main benefits of this tool is to eliminate errors made during the ordering process and address bottlenecks occurring in inventory management.

What Problems Does VMI Solve?

The production chain of the industry goes through a series of time-related steps, but given the automation of production, it is possible to forecast and average what will be produced over a certain period. Thus, the industry has a continuous production rhythm, which must be adjusted according to the proportion of demands from distributors and retailers.

With fluctuating monthly demands, if the industry's production maintains a fixed pace, the distributor's inventory may end up inflated with products that are not necessarily needed.

On the other hand, shortages and stockouts are common consequences of poor production management based on demand.

A buyer who did not purchase the proper quantity during the month may also pressure the industry for discounts on larger volume purchases at the end of the month, which can increase production costs.

This is where VMI comes in as a facilitator: since the distributor or retailer does not need to place orders directly, the industry takes care of keeping inventories adequately stocked based on direct data from its partners.

As a result, the industry avoids the risk of overproduction and manages sell-out issues better, while also enabling more effective incentive campaigns, for example.

Therefore, VMI is a favorable element in creating partnerships between buyers and suppliers. This is extremely beneficial to the consumer, considering the development of ECR (Efficient Consumer Response).

5 Main Advantages of VMI

For VMI to effectively eliminate flaws in inventory management, both parties must have technological and operational maturity in their supply chains.

The advantages for the industry and distributors when implementing an efficient VMI system are:

- By benefiting from the industry's process efficiency, the retailer can correct flaws by sharing control of its inventory.

- Increased revenue and margin by reducing stockouts or excess inventory.

- Reduced inventory levels through replenishments based on accurate consumption data and balanced inventory policies.

- Más tiempo para centrarse en actividades estratégicas para el crecimiento empresarial, desde el momento en que se automatiza la gestión de inventarios.

- Enhanced service levels and quality of customer service with products always available at points of sale.

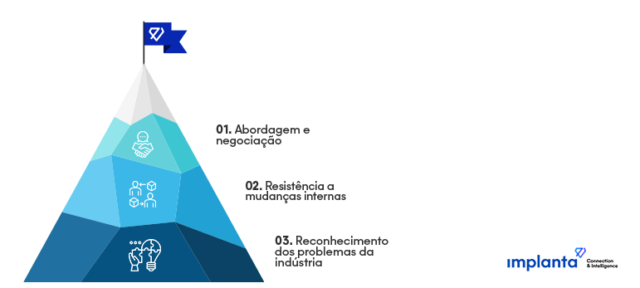

3 Challenges You Will Face in Implementing VMI

Just like any other strategic tool in the supply chain, it is essential to consider several factors before adopting it to modify business dynamics.

1. Approach and Negotiation: another important issue to address is the approach to vendor-managed inventory. A poorly executed approach can cause problems for the supplier and complicate the replenishment process.

There are various ways to approach implementing VMI. One good example is assigning a distributor's employee to work directly with the buyer.

Another possible approach is for the distributor to make visits to check for out-of-stock items and perform replenishments during the visit.

2. Resistance to Internal Changes: another notable challenge is that some managers still select a certain quantity of products based on their previous perceptions of the business, without considering concrete data that justify the decision.

Therefore, one of the significant challenges in implementing VMI is changing the routines of these individuals. The goal is to demonstrate that it's possible to obtain this information through advanced tools.

3. Recognition of Industry Problems: initially, one of the challenges is to identify business issues.

As this is a recent and disruptive technology, there is a need to understand the existing bottlenecks in the operation, such as large amounts of money lost due to stagnant or near-expiry inventory.

Thus, there is an opportunity to seek existing technological solutions that can help mitigate these impacts.

Industry 4.0, Technology, and VMI

The digitalization of the production chain is the most effective way to optimize processes and achieve higher service levels.

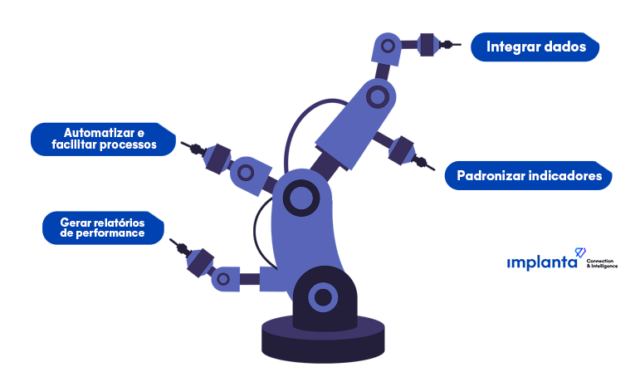

By adopting Vendor Managed Inventory (VMI), the industry is not only investing in efficient inventory management but also automating the crucial calculations that inform inventory status and sell-out performance.

To fully leverage the benefits of VMI, such as visibility into management, data integration, and efficient inventory maintenance, it is essential to use technological systems that automate calculation procedures and provide up-to-date information on sales and inventory.

Having a technological solution capable of doing this optimizes work and communication between business partners, as it incorporates elements that streamline work routines, such as:

- Integrate Data;

- Standardize Indicators;

- Automate and Simplify Processes;

- Generate Performance Reports.

Modernizing inventory control through technology makes complete sense in today’s market context. Those who do not adopt digital solutions risk losing competitive advantages and getting lost in the vast amount of data that industries continuously generate.

Reliability Among Supply Chain Partners

Another important issue is reliability among partners when establishing inventory management based on Vendor Managed Inventory (VMI).

Dado que el comprador da acceso a su stock al distribuidor, establecer alianzas basadas en la confianza y la credibilidad es sumamente importante para que el proceso sea exitoso y positivo para las partes involucradas.

Although increased production optimization is advantageous, the buyer relinquishes some of their control over inventory management. Conversely, the industry takes on the responsibility of managing and replenishing inventory without creating excess stock for the distributor.

Therefore, before adopting VMI, it is advisable to assess your partnerships and establish commitments that ensure the smooth operation of the supply chain without errors.

Data Accuracy is Essential

As we've seen, credibility in partnerships and the correct approach are critical factors for adopting an effective Vendor Managed Inventory (VMI) process.

Beyond this, there is one final, crucial factor: the accuracy and reliability of the data that underpin the process.

Today, producers and sellers are required to respond to consumers increasingly quickly. Any failure or delay can lead consumers to purchase from a competitor.

An element as fundamental as inventory cannot be subject to the flaws of ineffective methods.

Companies need to be more aligned in data gathering and decision-making. In this regard, data intelligence software can be a valuable ally.

The greater the data accuracy, the simpler the decision-making process, benefiting both suppliers and buyers.

To find the best solutions for your industry, talk to one of Implanta's experts now and make your management smarter and more precise!