Arriving at the supermarket and not finding a product on the shelf is not just a headache for the consumer. When this happens, the retailer loses a sale and might even lose customers.

According to a study by Mercado & Consumo, stockouts are the leading cause of sales loss in retail. To be precise, 41.2% of losses in the food retail sector are due to stockouts.

When a customer looks for a specific product at the point of sale and doesn't find it, this results in a series of negative consequences for those who produce that product.

Sometimes, the lack of a product at the time of purchase can lead to consumer frustration, declines in sales, and even increased sales for your competitors.

Want to learn more about stockouts, their main causes, and how to avoid them?

Follow these tips to understand and prevent the stockouts that impact all areas of retail.

What is a Stockout?

As old as the concept of inventory itself in industry and retail, a stockout occurs when a specific product from the manufacturer is not available in the retail store.

This issue can arise due to various errors in production and distribution within the supply chain, such as mistakes in inventory control, inaccurate data for buying and selling products, and a lack of synergy between retail demand and manufacturing delivery times.

Additionally, stockouts are linked to various errors in the buying and selling process between retail and industry.

Therefore, it is crucial to identify the origin and stage of the process that causes the stockout. It could be due to issues with retail control or errors in distribution by the manufacturer.

Main Causes of Stockouts

Between the manufacturing of a product and its sale to the consumer, there are various intermediate steps carried out by suppliers and partners that can encounter issues.

The purchasing department might be using outdated information, which prevents it from scheduling restocks according to actual needs.

Similarly, this lack of control in the warehouse often stems from management problems, such as the absence of integrated systems and poor control over the flow of goods.

Therefore, the focus should be on the accuracy of information and access to reliable data, which helps optimize decision-making for those involved in inventory management.

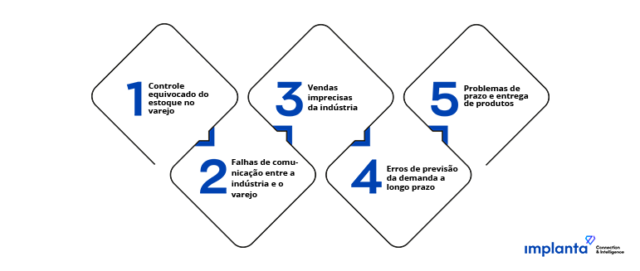

Finally, keep an eye on some key factors that might be the source of stockouts:

1. Mismanagement of Retail Inventory

It is common to see sales and restocking issues arise due to inadequate control of retail inventory.

Inadequate inventory control in retail can lead to a series of errors related to demand. As a result, the manufacturer might supply either too many or too few products compared to the required quantity.

A more intelligent inventory management process can even include support from the manufacturer.

2. Inaccurate Sales Data from the Manufacturer

From the manufacturer’s side, it is common to find managers who view sales as the ultimate goal, which can be detrimental to the long-term growth of the industry.

In the supply chain cycle, merely making sales is not enough. It is also necessary to sell intelligently by considering which products in your catalog are selling well and which are not.

With accurate data and ongoing communication with retail, the manager can make the sales process less prone to errors for both parties.

3. Issues with Product Timing and Delivery

The logistics process is also a crucial part of the production and sales system, whether from the manufacturer or the retail channel.

Therefore, to determine the precise demand at a given point of sale and to ensure correct restocking of products available in the market, it is also essential to know the transportation time of the product to the retail location.

4. Long-Term Demand Forecasting Errors

Understanding the assortment of available products and the seasonality of retail demand can help reduce stockouts more frequently.

Moreover, recognizing different demands based on seasonality is key to understanding specific drops in sales and not necessarily attributing them to errors.

For example, knowing that demand for ice cream is lower during cold weather is information that, when combined with intelligent inventory management, prevents stockouts when the weather warms up again.

5. Communication Failures Between Manufacturer and Retailer

Maintaining constant communication with your production or distribution channel is another crucial aspect to address regarding stockouts.

In this context, a lack of transparent data and proper monitoring can lead to errors that have serious consequences for both parties.

Therefore, good communication and integration between producers and retailers can prevent stockouts, avoiding losses for everyone involved in the supply chain.

4 Types of Stockouts

A stockout in retail can cause various problems for the business. Therefore, we have listed below each possible type of scenario:

1. Catalog Stockout

This occurs when a customer searches for a product that is available for sale but has not been listed or priced.

2. Phantom Stockout

This happens when the company has the product in stock and on display, but the customer cannot find it. The cause is usually related to poor organization at the point of sale.

3. Display Stockout

This type of stockout occurs when the products on the store shelves are sold out, but the company has additional stock stored away.

It is one of the worst types as it results in a lost sale.

4. Supply or Purchase Stockout

This is often considered the most "classic" type of stockout. It occurs when a specific type of product (such as a particular color, shape, size, etc.) runs out.

What Are the Consequences of Stockouts for the Business?

In summary, stockouts cause both manufacturers and retailers to lose sales.

It is important to understand that a percentage of people who go to the supermarket in search of a specific brand might end up buying a similar product, while another group may abandon their purchase altogether.

It is possible that someone who goes shopping, upon noticing the absence of a particular product, might decide to leave and search for another supermarket to complete their purchase.

In this case, everyone involved in the supply chain ends up losing.

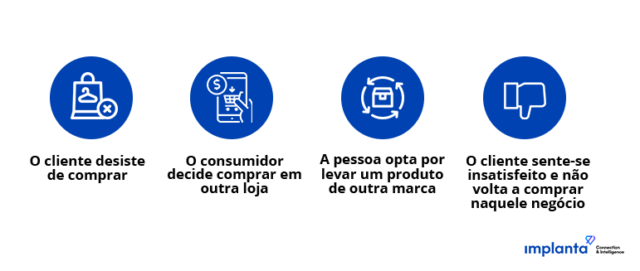

Therefore, the main negative consequences of stockouts are:

- The customer decides not to make a purchase;

- The consumer chooses to buy from another store;

- The person opts to take a product from a different brand;

- The customer feels dissatisfied and does not return to that business.

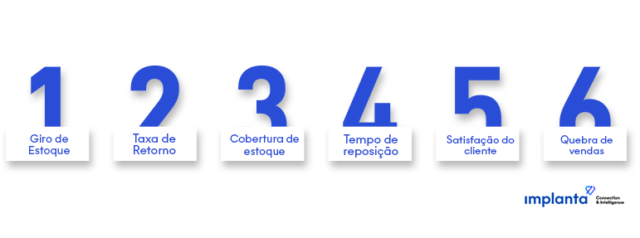

Stockout Indicator

Inventory indicators are quantitative and qualitative metrics that show the performance of a company's product stocking and can be used as a management tool for controlling merchandise and monitoring results.

Thus, the more efficient the inventory management, the better the understanding of the business’s capacity and the easier it will be to control merchandise storage. This helps in avoiding sales losses and overstocking.

Monitoring these indicators is crucial, as they provide comprehensive knowledge of the entire process within the sector.

With this information, it is possible to develop strategies to optimize processes, reduce costs, and prevent waste.

The most common indicators that can assist you in managing your industry are:

- Inventory Turnover

- Return Rate

- Stock Coverage

- Replenishment Time

- Customer Satisfaction

- Sales Loss

How to Calculate Stockouts

Another important aspect is knowing how to measure stockouts. The calculation can be done in various ways.

The most common formula is:

Stockout Rate = (Items Out of Stock ÷ Total Number of Products in Store) x 100

This calculation is quite flexible and can be performed at the end of each shift to better understand the turnover of each product in the store.

Setting a safety stock level based on your estimated turnover is a good way to mitigate stockouts and make the purchasing process more effective.

How to Avoid Stockouts

So, how can stockouts be reduced or avoided?

Among several methods, using appropriate management software and systems that meet your needs and provide reliable data to facilitate your purchasing process is essential.

By implementing the right tools, you won’t need to worry about calculating stockouts, for example, as the right software will provide you with this and other data ready for interpretation.

It is evident that companies and industries investing in new technologies show greater growth compared to those that do not, as they have better data for decision-making.

Thus, quality management software offers better continuity in the production cycle, benefiting both retail and industry while minimizing resource or product waste.

How Implanta’s Distribution Visibility Solution Reduces Stockout Rates

Building an analysis of inventory management involves investing in technology to address this type of obstacle.

Initially, this solution focuses on collecting information from distributor and retailer inventories.

It is essential to remember that reliable and accurate data software is available to you. Implanta offers a range of industry solutions, including Distribution Visibility and Demand Forecasting.

The Distribution Visibility platform captures data directly from the distributors' ERP, allowing the industry to have visibility of its products in the Supply Chain.

In this way, you can monitor your Sell Out and the stock position of distributors and resellers on a daily basis.

In summary, Implanta’s software solutions can reduce stockouts by up to 80%, unlock up to 20% of the distributor's working capital, and increase sales by up to 10%.

To learn more about how Implanta's solutions can help you leverage data intelligence to reduce stockouts, contact one of our specialists..