Tracking sell-out numbers is a crucial element in managing industry resources and essential for both short-term and long-term decision-making.

However, many managers still face challenges in obtaining data that ensures security, effectiveness, and accuracy.

The reasons behind ineffective decisions based on sell-out data are diverse: inaccuracies in data, delays in updates, lack of interest from channels in sharing sell-out information, and even managerial resistance to adopting new working methodologies.

Therefore, understand now the importance and some of the benefits of obtaining daily updated sell-out data.

Sell-out and Industry 4.0

Keeping track of inventory, distribution, and sales numbers has always been a challenge for companies in the production chain, particularly at the industrial production scale.

The major challenge in managing these processes lies in handling the large amount of data that needs to be collected, organized, and interpreted.

How to monitor sales at the point of sale (POS)? How to predict demand based on these numbers? What short-term and long-term decisions to make based on this data?

With these questions in mind, industry managers resort to various methods aimed at optimizing the processing of this data.

Some make projections based on distributor orders, others manage inventory directly with distribution channels, and there are other methods to forecast and meet demands.

Amid a myriad of options on how to process direct consumer sales figures, there are more and less effective methods for decision-making in the process.

The advent of digitalization in companies, especially in industries, dubbed Industry 4.0, has required businesses across all sectors to embrace technology-focused solutions and their advantages.

Therefore, it is increasingly common to see industrial companies investing in cloud data storage tools, artificial intelligence, digitalization of various processes, among others. Those who do not adapt to new business models and tools may, for example, limit their short-term growth.

In 2020, according to a survey by the National Confederation of Industry, there was a significant increase in the number of companies adopting up to four new Industry 4.0 technologies, some of which demonstrated substantial growth and increased hiring.

Sell-out and its relationship with new technologies

As we've seen previously, the landscape of technological changes brought about by Industry 4.0 has enabled a range of innovations, contributing to overall industrial growth. But when it comes to sell-out data, what is its connection to these new technologies?

With the increasing difficulty for industries to manage sell-out data precisely and with reduced margins of error, the automation of data collection and interpretation processes has become essential.

For example, prior to using digital management and integration tools, purchasing and sales processes in the industry underwent bureaucratic procedures that were time and resource-intensive.

The bureaucracy of these processes also affected data collection and interpretation, leading to a range of issues and less well-informed decisions.

Today, saving time is crucial for these companies to streamline their decision-making processes. Wasting time translates to wasting resources and, in many cases, making erroneous decisions.

In order to organize, process, and facilitate better interpretation of large datasets, data intelligence emerges as the foundation for software and services that handle the collection and prioritization of data to facilitate decision-making processes.

In the production chain, a massive amount of data is generated daily, making this characteristic valuable for the industry. This data requires organization and interpretation so that managers can make the right decisions in production.

It is in this scenario that a range of solutions and software come into play, allowing for faster data collection and interpretation for companies.

Data intelligence and benefits for sell-out

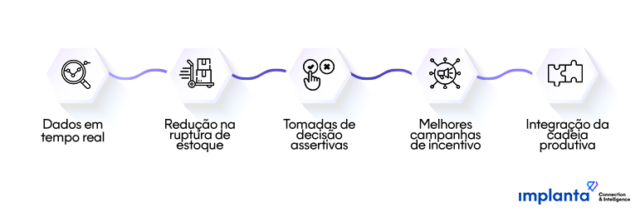

We've seen that data intelligence sets a promising future for all areas of the supply chain. But what other benefits can data intelligence-based software bring to the industry? We can mention hundreds of these benefits, but some of them include:

Real-time data

Given the urgency for accurately interpreted data as quickly as possible, obtaining real-time sell-out data is one of the key advantages of adopting data intelligence software.

Doing so streamlines processes and provides managers with a better understanding of the production landscape at any given moment.

Real-time updates also enable more accurate projections based on the data presented. This leads industries to take a leading role in their production chain and set the pace among the chain's stakeholders.

Reduction in stockouts

We know that stockouts can lead to a series of negative consequences for everyone involved in the supply chain.

Distributors and retailers lose sales, and the industry needs to compensate by increasing its production rate and consequently spending more on it.

The adoption of competent software allows managers to anticipate this process and not only ensure product availability at POS in the right quantities for the period but also the replenishment of other products in the catalog that do not sell as well as the best sellers, thereby increasing assortment for consumers.

Effective decision-making

It is inevitable to conclude that the more accurate and precise sell-out data are, the better informed the decision-making process of managers becomes.

We have seen that dealing with bureaucratic processes costs valuable time and money resources. Therefore, the same applies to decision-making that does not result in what was planned.

Accurate data presented intelligently results in a lower margin of error, which brings benefits to both the industry and distributors and retailers.

Improved incentive campaigns

Do you know which salespeople from your distributors are achieving truly positive sales results for your products?

This can also be verified through well-analyzed sell-out data. Rewarding the right partners enables better motivation, potentially resulting in a greater increase in sell-out numbers.

Supply chain integration

Lastly, but no less important, accurate data allows for greater industry integration. Many of these solutions enable transparent management and purchasing processes.

Agreements based on Vendor Managed Inventory (VMI), for example, ensure there is a partnership and greater trust between producers and distributors, while eliminating the bureaucratic process of replenishment orders.

Quality software based on data intelligence can support this entire process.

How to obtain daily and accurate data?

But after all, how can one acquire these software solutions and make data intelligence an ally of industrial production?

The first step is to rely on specialized consultancy and software that ensures greater data accuracy.

Integrating your distribution and sales channels requires software that guarantees reliability and precision when making decisions.

Turning data from a problem to be solved into an ally that will benefit your company and all other channels in the supply chain is essential.