The production and distribution of various products to reach the end consumer at the right time and in the correct quantity constitutes a complex process involving multiple stages.

One of these stages involves efficient inventory management across all links of the supply chain, ensuring proper planning and actions tailored to market demands for each product.

Inventory management is crucial because without effective control, several issues can arise in the product cycle and throughout the production chain, such as stockouts or excess inventory.

The latter can be particularly damaging and detrimental to both industry operations and distribution channels, as excess inventory results in losses and unnecessary expenses.

Excess inventory stems from a variety of factors, and its consequences can weaken not only the operations of supply chain participants, but also their relationships.

However, like many other issues affecting the production chain, there are solutions that can mitigate the impact of excess inventory and transform it into a manageable problem for industries and partners.

To gain a deeper understanding of excess inventory, its origins, and the best ways to address it, continue reading the following content and learn more about this topic.

Excess Inventory and Its Main Causes

As the name suggests, excess inventory occurs when the number of products in stock exceeds the previously planned amount. This leads to expenses related to storage and losses due to expired products or tied-up working capital.

However, excess inventory can be caused by various factors. If not identified and remedied correctly, these factors can lead to additional resource costs for industries and distributors.

Among some of the primary causes of excess inventory, the following reasons can be highlighted:

1. Poor Production Planning

Poorly planned production can also be a reason for excess inventory.

Production that is inadequately planned may stem from inaccurate information and a lack of greater predictability regarding demand from industries.

This can cause production rates to deviate from the optimal pace and unnecessarily burden industry operations.

2. Communication Errors

El exceso de stock suele producirse debido a la generación de “ruido” en la comunicación entre los canales de distribución y las industrias, por ejemplo.

When there is a lack of transparency or accuracy in the data, information, and orders communicated from distributor channels and retailers to industries, production ends up suffering from these errors, resulting in overproduction.

3. Lack of Channel Integration

Integration among the links in the production chain is crucial for ensuring operational synergy and long-term positive outcomes from partnerships.

Lack of integration can lead to production errors, logistical issues, inventory management mistakes, and, of course, reduced sales margins.

4. Inefficient Inventory Management

Last but not least, inventory management constitutes a critical aspect of stock management.

By categorizing products, inventory management provides clearer visibility into what needs attention within a specific product catalog.

Inefficient inventory management can lead to confusion in stock management, resulting in common errors such as failing to differentiate between available quantities and SKUs.

This lack of accuracy regarding overall stock numbers complicates the sales process for other channels. Unclear number definitions lead to bureaucratic procedures and delays.

Idle Inventory and Its Consequences

As discussed earlier, idle inventory originates from various issues and results in detrimental consequences for all stakeholders in the production chain.

These consequences can impact all operations within the chain and all stages of the product cycle.

Some of the consequences of idle inventory may include:

1. Low-Quality Inventory:

We know that excess inventory leads to higher storage costs and demands significant resources and time.

Additionally, there is a risk of theft, damage, expiration, and other factors that can turn a ready-to-sell product into an out-of-stock item.

2. Risk of Stockouts:

It may seem contradictory to talk about stockouts when dealing with excess inventory. However, this can also be a consequence of excess inventory.

Excess products may mean that your distribution channel won't purchase new products for a while or that these products will still require transportation and storage time before being stocked, potentially leaving the distribution channel, and consequently the consumer, without the product for a period of time.

3. Ineffective Product Assortment:

Another common issue with excess inventory is ineffective product assortment.

Excess of one product can mean shortages of others, and vice versa, which results from uncoordinated production, as discussed earlier.

Excess inventory causes imbalances in supply and subsequently affects the variety of products available to customers, directly leading to reduced sales.

Effective Inventory Management: How to Do It?

Now that we've discussed the main origins and consequences of excess inventory, it's time to explore the best ways to address the issue.

One of the primary approaches to tackling excess inventory is by integrating stakeholders across the production chain, ensuring seamless connectivity between operations.

There are several ways to achieve this, one of which is through an integrating software that facilitates data exchange and automatic insights. This not only saves time but also reduces resources spent on bureaucratic processes.

Another viable solution is adopting tools that provide direct visibility into sales and real-time tracking of products at the retail level.

By accessing real-time sell-out data, it becomes possible to plan production more effectively. This ensures more efficient inventory management, leading to increased sales and improved product lifecycle management.

While they play a smaller role in inventory management itself, well-executed incentive campaigns can also help channels and partners sell products that were previously stagnant in inventory more easily.

ABC Analysis: How to Use in Inventory Management?

One of the tools that helps balance inventory management is the ABC Analysis.

Its origin stems from the theory of the Italian economist Vilfredo Pareto, who, through a study, found that 80% of wealth was concentrated in the hands of just 20% of the population.

Since then, other studies have followed the 80/20 proportion for cause and effect analysis.

The ABC curve is a classification method used to separate items by their importance or impact, typically focusing on a smaller number of items.

Items are classified as:

- Class A: of highest importance, value, or quantity, comprising 20% of the total - these may be inventory items with a demand of 65% in a given period;

- Class B: of intermediate importance, quantity, or value, comprising 30% of the total - these may be inventory items with a demand of 25% in a given period;

- Class C: of lower importance, value, or quantity, comprising 50% of the total - these may be inventory items with a demand of 10% in a given period.

ABC Classification is an important tool to assist in decision-making processes, as it provides a comprehensive view of company management.

In inventory control, this methodology is used to classify and identify the quantity of products, pinpointing those that contribute most to revenue or have the highest turnover.

In a business's sales cycle, certain products hold more value than others and thus require greater attention.

By applying ABC Classification to inventory, the company gains the following advantages:

- Inventory aligned with demand

- Improved financial health of the company

- Effective marketing campaigns

- Optimized logistics

- Strategic pricing

Inventory Accuracy, Why Is It So Important?

Inventory accuracy refers to having precise information about stocked items.

In other words, everything in your warehouse should also be reflected in the system: how many items are in stock, their locations, expiration dates, etc.

Recording everything stored indicates the reliability level of the inventory. The higher this index, the greater the inventory accuracy.

Conversely, the lower the index—meaning discrepancies between the inventory and the system, where an item is recorded in one but not the other—we say the inventory lacks accuracy.

Ensuring inventory accuracy brings several benefits to a business, such as:

- Precision in decision-making

- Efficiency in inventory management

- Cost reduction

- Speedier deliveries

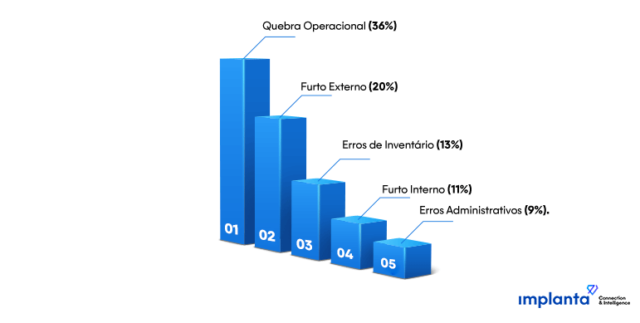

Low inventory accuracy can result in considerable losses.

A study by the Brazilian Association for Loss Prevention (Abrappe) indicated that in 2018, Brazilian retail lost approximately R$21.46 billion (or 1.38% of its net revenue) due to inventory discrepancies.

The main reasons for losses were:

operational breakdown (36%)

external theft (20%)

inventory errors (13%)

internal theft (11%)

and administrative errors (9%)

In other words, a significant portion of these problems could be solved, or at least minimized, by inventory accuracy!

Inventory Control: You Need to Monitor Your Data

Data analysis is crucial for business operations.

When managers lack a comprehensive view of their product performance at points of sale, it's difficult to plan actions that place the business in a favorable market position.

Monitoring data means understanding how a product meets consumer needs and whether its distribution is carried out correctly.

Therefore, tracking metrics ensures decision-making that enhances inventory management, distribution, and industry sales.

It's also important to note that monitoring remains a challenge for many companies, as inventory may be spread across multiple locations and accessing this information isn't straightforward.

Therefore, to ensure products are always available to consumers, it's essential to work with integrated indicators with suppliers. This ensures that the replenishment rate aligns with company demands.

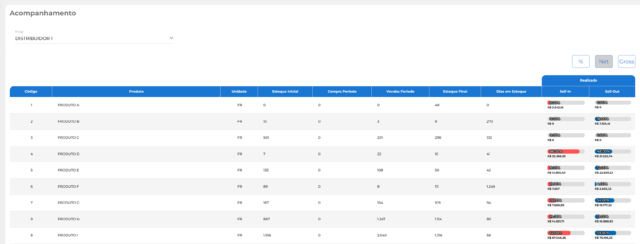

Smart Inventory Is What You're Looking For? Count on Implanta!

Using the right tools makes all the difference in smart inventory management, whether it's for industry, distributor channels, or retailers.

To make the best decisions for your production, it's essential to use integrating software that provides accurate information and insights for a strategic and precise view of production and sales.

Among the various functionalities offered by Implanta's solutions, our reports show you initial and final inventory, optimal inventory levels, days of inventory sales, reorder point, shelf break anticipation, and opportunities for sales (sell-in).

We offer tools designed for the industry with 99.8% accuracy of data collected directly at the points of sale, ensuring you don't rely on inaccurate data that could lead to wasted resources.

To get the best data intelligence solutions for your industry, talk to one of Implanta's specialists now. Make your inventory management smart and effective!